|

|

Post by casias on Dec 4, 2015 19:06:04 GMT -5

Duplicate post.

|

|

|

|

Post by casias on Dec 5, 2015 11:51:43 GMT -5

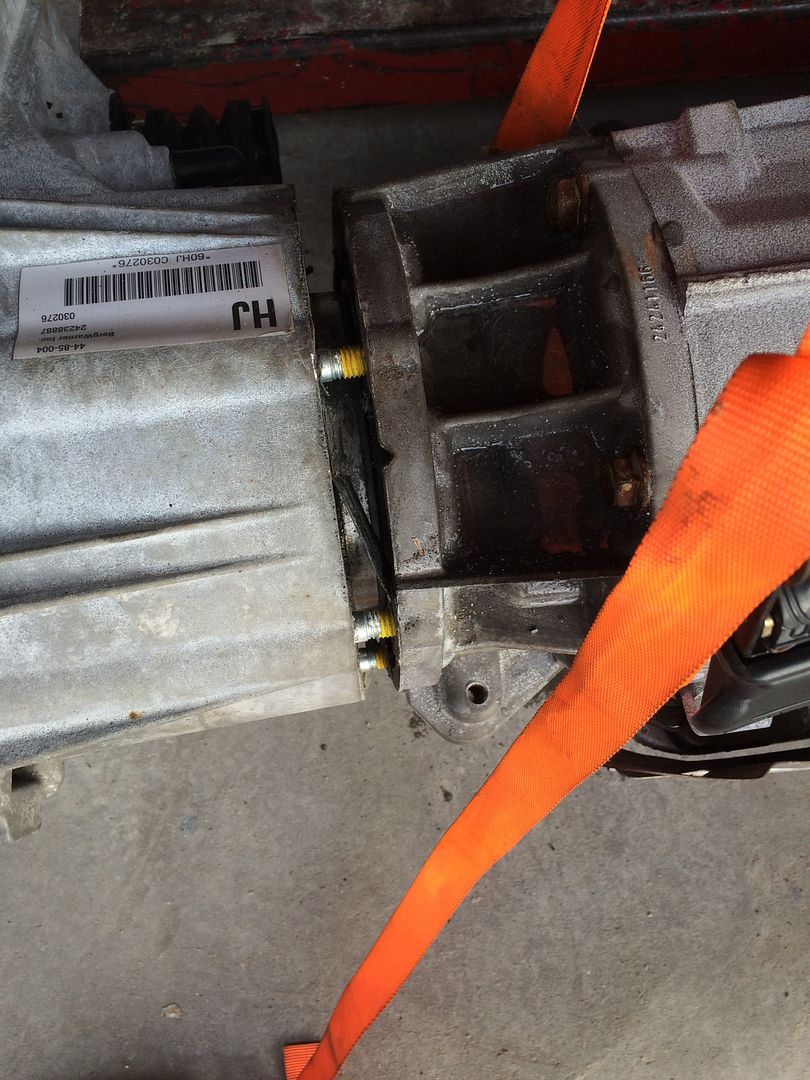

I had a heck of a time getting the transfer case separated from the transmission. Everyone on youtube seemed to have them just "fall off", when they loosened the bolts. Not my luck. It was stuck like crazy glue. I was concerned about nicking the mating surface, and I didn't want to bang on the aluminum case with a hammer and crack it, so I thought about it for awhile. Finally, I went to a friend's house, knowing he had just pulled the transmission out of a jeep. Turns out, the spacer between the transmission and transfer case is dry, so no real fear of nicking the mating surface. \ So I used a drywall knife and hammer to drive the gasket in all the way around, and gently separated the cases.   |

|

|

|

Post by casias on Dec 6, 2015 9:29:17 GMT -5

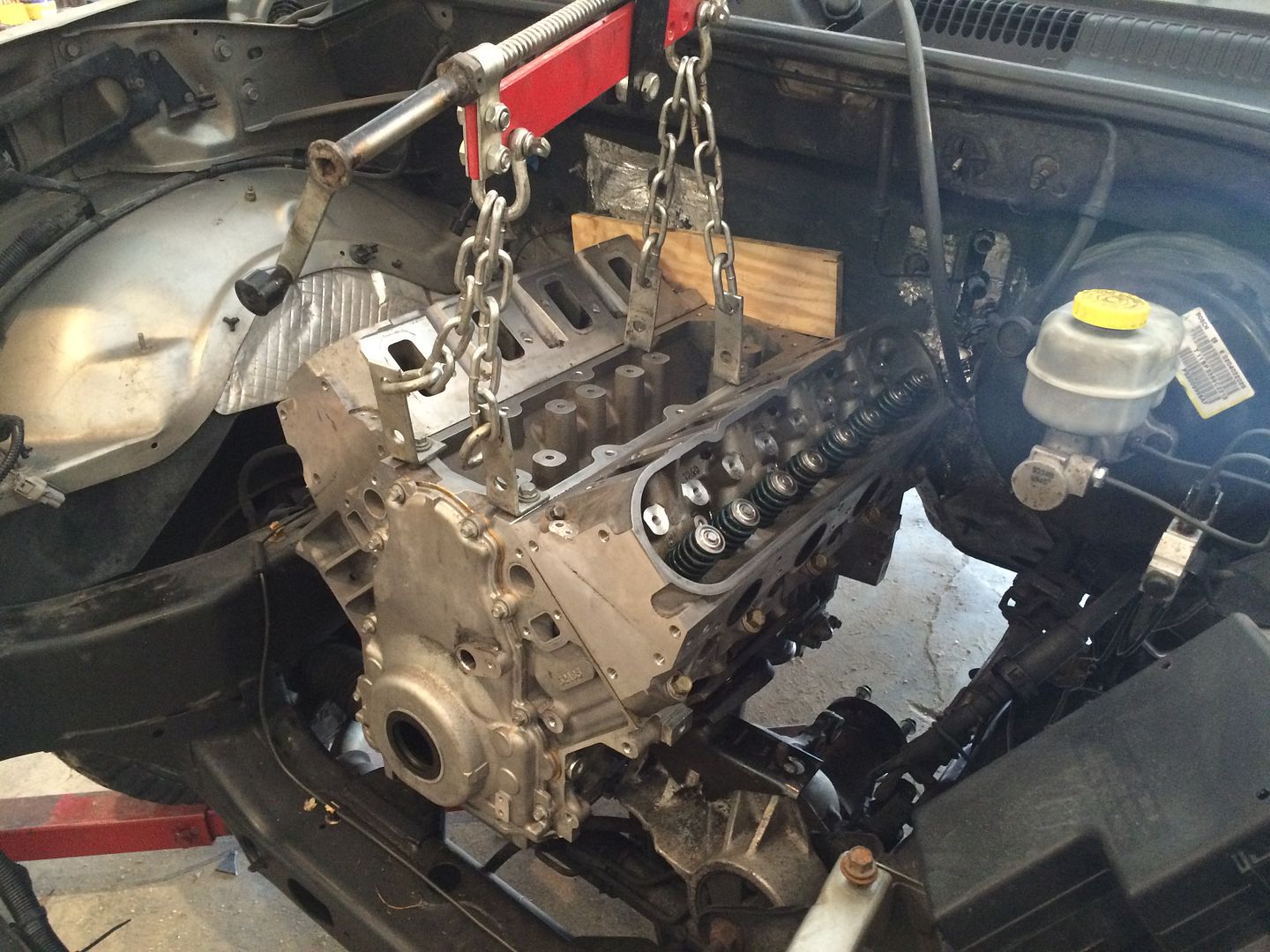

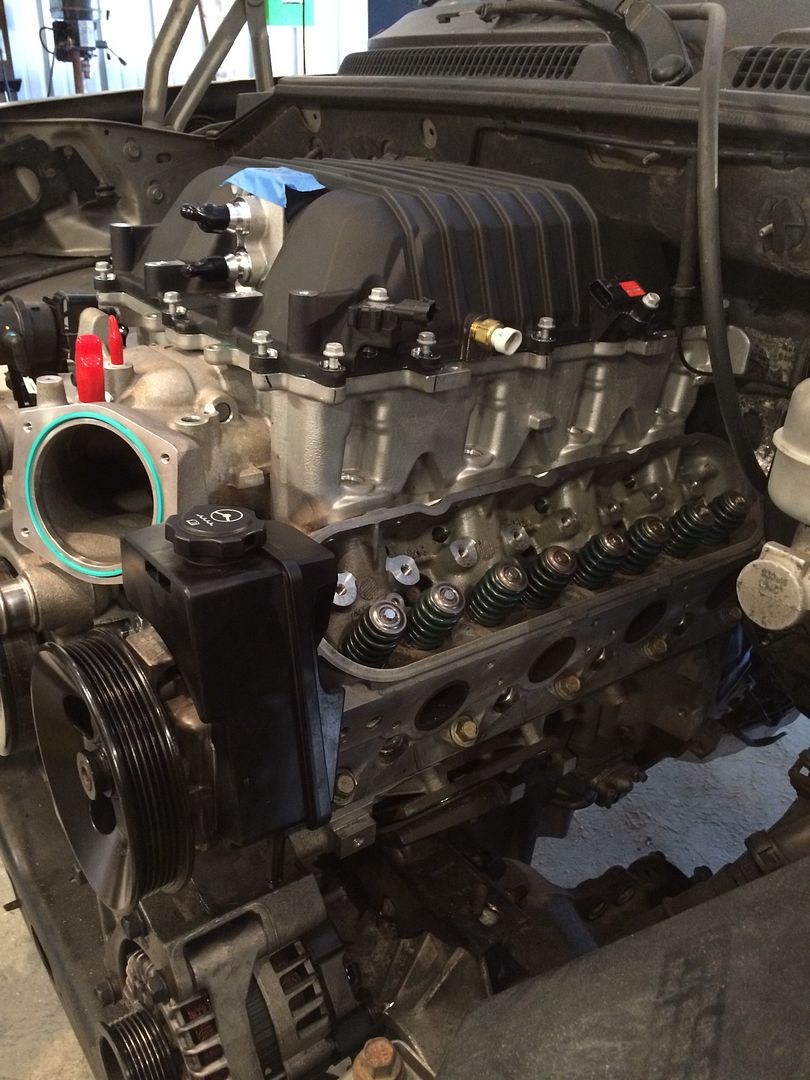

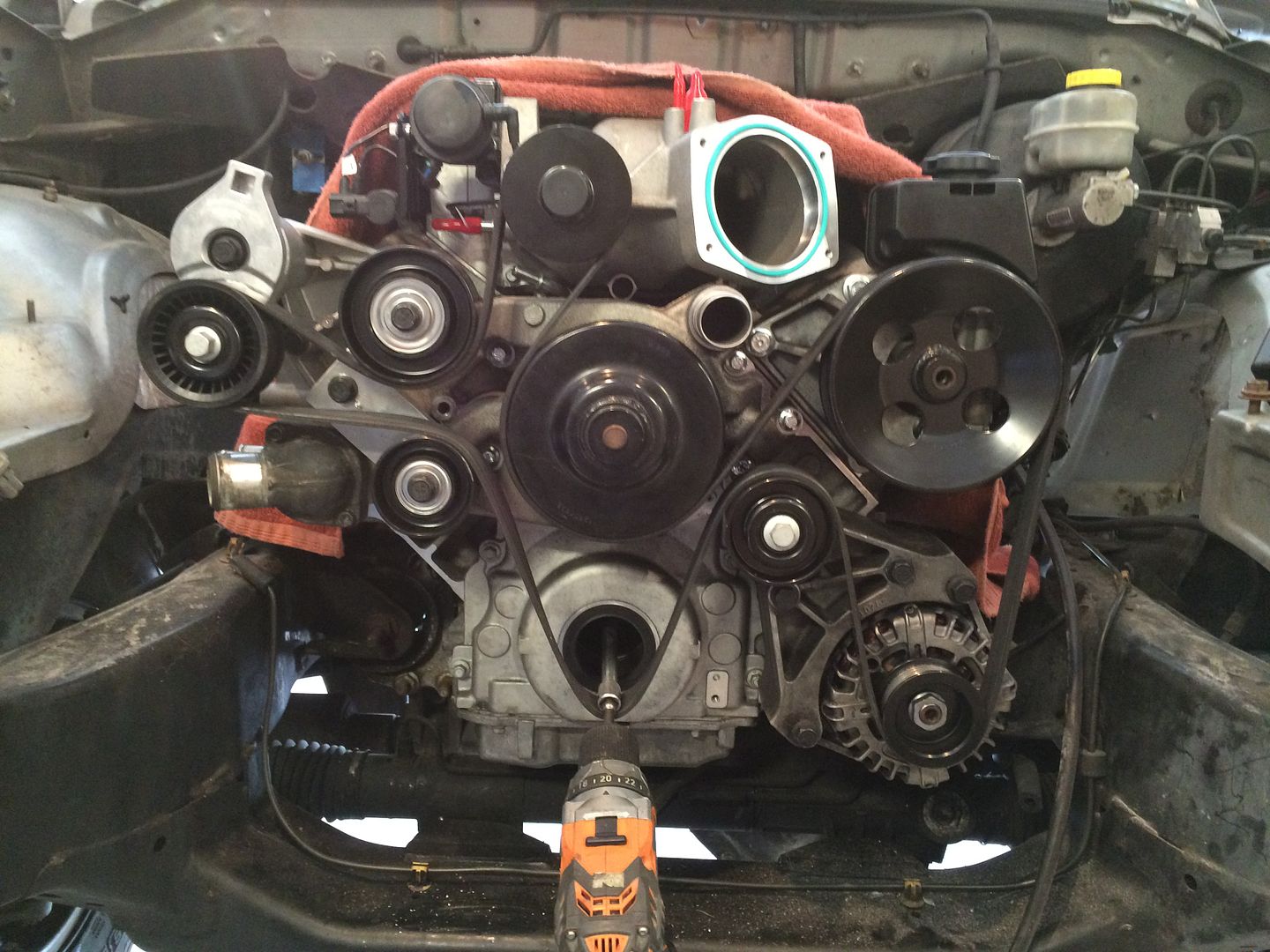

Days like today are fun when you are working on a project like this. I had purchased a truck oil pan, which arrived this week. Putting it on my plastic mock-up block, and BOOM, it hits the front axle. After looking at it for a few minutes, it seemed I could move the engine back towards the firewall about an inch, to clear it. I made a new set of adapter plates, and dropped it in. No problem. So I put in the LS3 engine for final fit. There is ample room on all sides, including room for headers. So far, this is even easier than a 2WD, which was pretty easy. So that's saying something. The real engine sitting in the engine bay.  Looking up from the bottom, driver's side clearance for headers.....HUGE. Oil filter, no problem.  And passenger side. Also plenty of clearance. Check out the room for the starter also !  Front axle clearance.  Driveline angle using pvc pipe.  And the 6l80, AWD transmission. This transmission and transfer case is the same length (46 inches) as the 46re that came out. So the crossmembers clear, and I think I may even get away with using a stock transmission mount. For those wanting selectable high and low range trnasfer case, the dimension is the same as this Borg Warner 4485.   Future.....  |

|

|

|

Post by hammerdown on Dec 7, 2015 15:03:16 GMT -5

Oh Snap! Putting the LSA blower on top.... This is going to be a sweet build!

|

|

|

|

Post by casias on Dec 7, 2015 19:38:19 GMT -5

Oh Snap! Putting the LSA blower on top.... This is going to be a sweet build! Yes. That is why I am doing an AWD Durango instead of another Dakota. The slowest part of this so far has been getting enough CTS-V pistons. I thought they would be easy to find, but no such luck. Now I have 7 pistons and 8 LSA rods. Waiting for the 8th piston. |

|

|

|

Post by casias on Dec 12, 2015 12:33:05 GMT -5

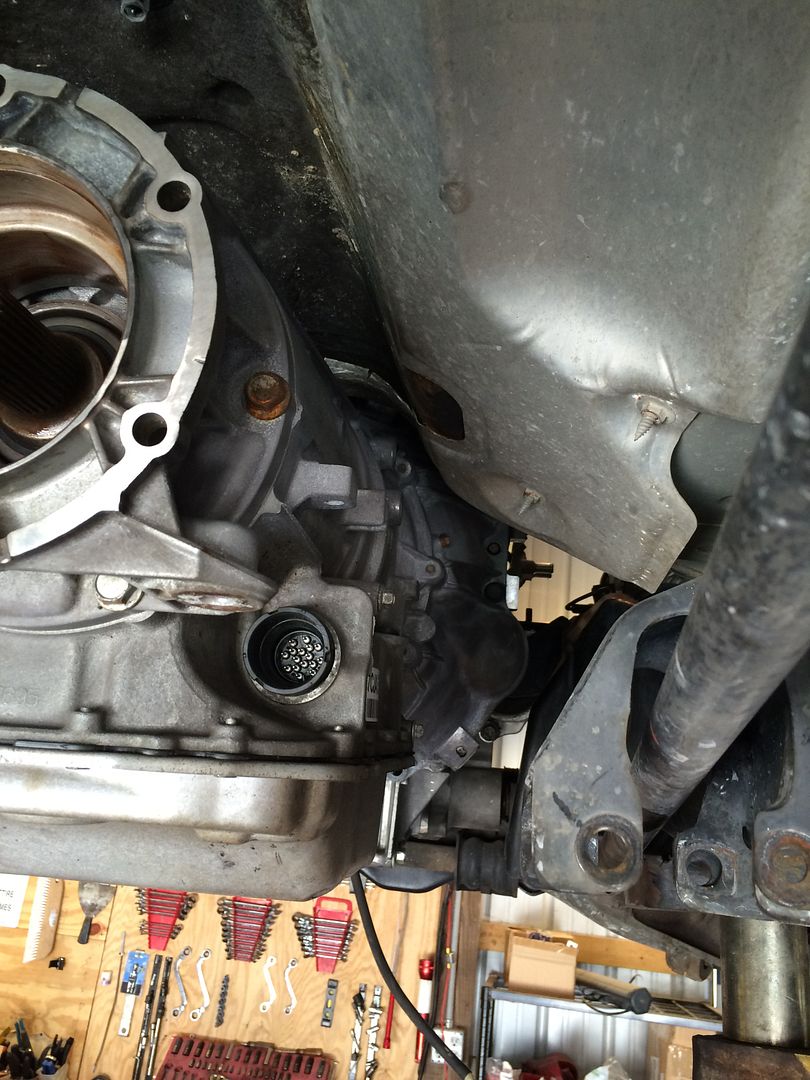

Update this week is bitter-sweet. I really wanted to use the Borg-Warner transfer case that came with the 6l80 transmission I bought, but......it is too wide. It would fit between the frame rails, if someone was planning a solid front axle swap, but the torsion bars cause interference in the independent front suspension setup. So I went back to the original 231 that came in this truck. Turns out, Novak makes an adapter kit to fit the 231/242 to the 6l80/6l90....fantastic! So, for anyone wanting to do this swap with the 6l80 or 6l90 and retain the independent front suspension, you can re-use the 231 or 242 transfer case from the Durango (depending on whether it is AWD or 4WD), and save buying a new transfer case. See....bitter/sweet. The upside of these transfer cases is that they are plentiful, strong, and have huge aftermarket support to make them stronger. So I bought a 242 off of ebay for $165 shipped to my door. Moving on...... The transmission is in, and has plenty of clearance. The tunnel on the 4wd Durango is generous, just like the engine bay. No interference issues at all. Transmission went in. Took about 10 minutes with the usual wrestling and wiggling.    Now, how about that driveline angle. I use string and gravity. I have this diy gauge, made with string, a piece of aluminum tube and a washer.   I don't like lying on the floor, so I compress the rear axle using a 2x4 and floor jack, until the rear springs are fully compressed and the frame is just lifting off of the lift pads.   And make a mark on each side of the string (it's hard to accurately mark directly under the string).  Any question about how much the rear axle angle changes when it is not compressed? Here is the angle when not compressed. Set up the transmission to match that, and your driveshaft would wobble for sure.  And jacking the transmission up to match still leaves enough room in the tunnel. It is snug, but won't require any cutting or hammering. The engine has about and inch clearance to the firewall. Perfect.  |

|

|

|

Post by casias on Dec 13, 2015 8:28:04 GMT -5

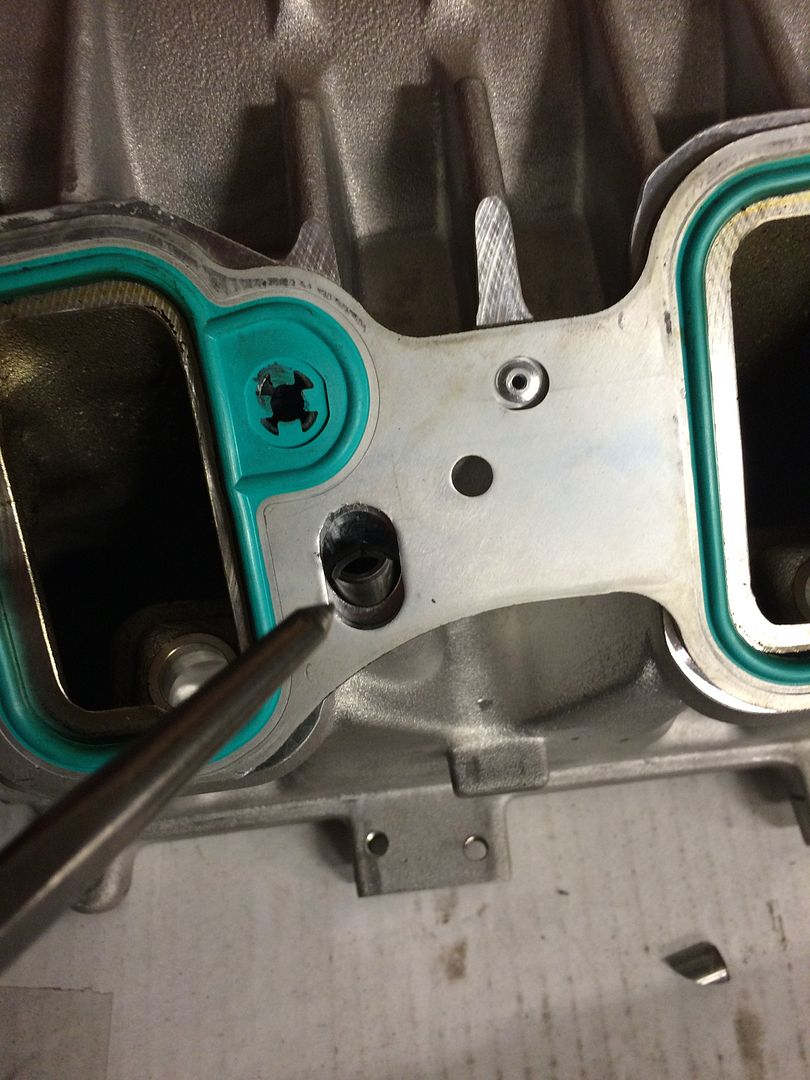

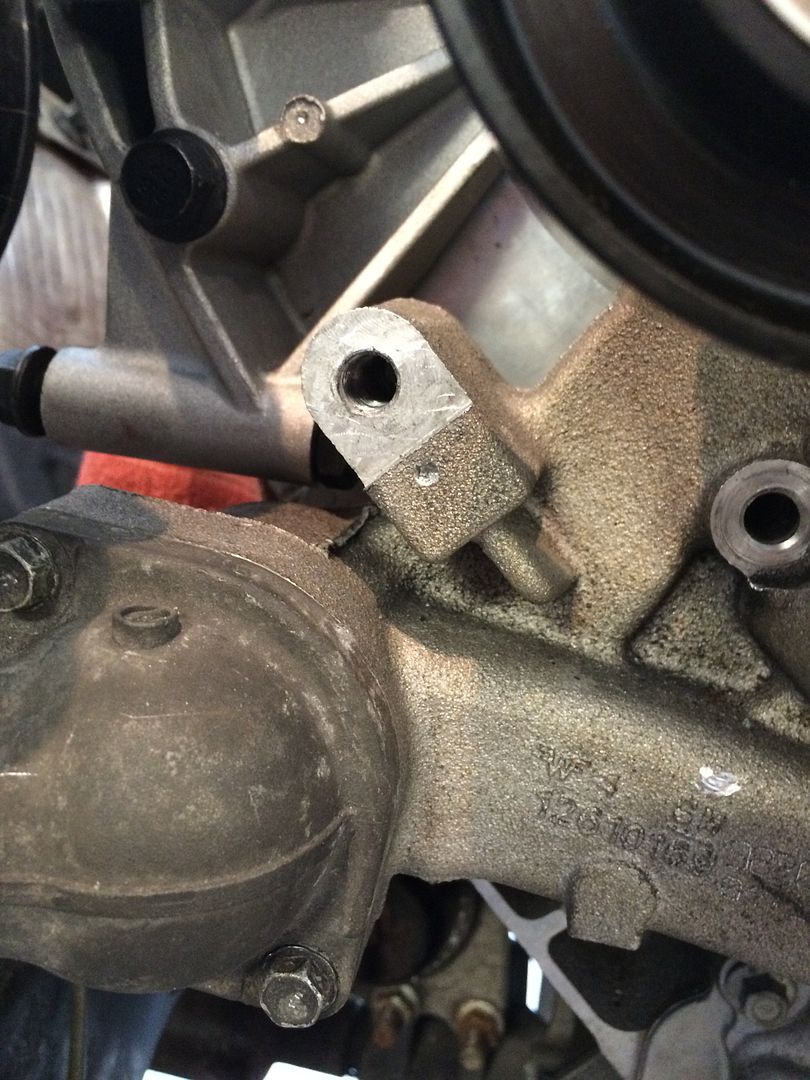

Sunday morning Stupid Pet Tricks This project is moving so slowly for a couple of reasons. 1) I haven't worked on a 4x4, so everthing I am doing is new to me. 2) I am working more, with less days off 3) I can't get freaking parts. I have a bunch of stuff ordered, but not in. Waiting..waiting...waiting. But, whenever you do these swaps, you run across little things that eat up time. I am trying to document all of the little things that happen, to give an idea how I get around some of these things. I couldn't do it without the vast amount of knowledge available on the internet forums. Even though I have started a facebook page for my builds, It isn't the same. The information is not searchable, so I will always rely on internet forums for the exchange of ideas. Please help support this. Trick 1 The LSA supercharge I am using had an alignment tube in the passenger side mating surface. I can only assume that LSA cylinder heads have a hole for this? I have never seen one, but it caused me trouble with my LS3 heads. So.....I hit ls1tech. I was told to "break it". Ok. Alignment tube.  I chose to hit it with a punch. Somehow, swinging at it with a hammer on the mating surface seemed wrong.  And, BAM! It broke just as described.   Trick 2 The engine block already had two alignment dowels for the transmission bell housing, when I noticed the transmission bell housing also had an alignment dowel. Ooops. So I tapped at it and tapped at it, and heated it, and soaked it in PB blaster, and heated and quenched it, and hammered some more. Tried vice grips, pipe wrench and huge channel locks. It wouldn't budge. Thank you GM, for putting a steel alignment dowel in an aluminum bell housing. GM engineers need to go back to metallurgy 101. So, after hitting the forums, I had two suggestions. 1) Drill the end and thread for a slide hammer 2) Weld a nut on it I chose number 2. The welding added quite a bit of heat, which probably didn't hurt, and the nut held firm. I couldn't budge it with a breaker bar, without rolling the transmission all over the place, so I chose to hit it with an impact. If it broke the bell housing, they are replaceable on a 6l80, but more time waiting for parts. I started on low, and progressively moved up until it began to spin. My concern was breaking the ear off of the bell housing. Fortunately, it worked.   |

|

|

|

Post by 93ragtop on Dec 15, 2015 9:48:42 GMT -5

Casias, Will using the dodge transfer case still give you a speed sensor that is compatible with the LS computer? I would think it will need one for the shifting of the transmission. But of course, I could be way off base, again!!

|

|

|

|

Post by casias on Dec 15, 2015 10:37:53 GMT -5

The TCM and all of the signal comes from the transmission. I am going to use the escalade ECU and wiring harness. The escalade transfer case does not have a single sensor in it. That is how Novak is able to offer an adapter. Gotta love GM. Keep it simple.

|

|

|

|

Post by 93ragtop on Dec 15, 2015 18:32:48 GMT -5

That is good to know...... With the speed sensor being in the transmission and not the transfer case would work well for the older 231 case (88-92) They have a cable driven speedometer. So my thinking is, the transmission sensor would supply what the LS computer needs for vehicle control, but with the mechanical hookup on the transfer case, that could continue to run the factory Dakota speedometer. Off hand, would you know if the 4L60E and 4L80 4wd transmissions have the speed sensor as well?

|

|

|

|

Post by casias on Dec 15, 2015 21:39:14 GMT -5

I'm not sure about the 4l60 and 4l80 transmissions. I have only worked with the 6l-series. You might try searching ls1tech or ls1truck to see if someone has discussed it.

|

|

|

|

Post by casias on Dec 23, 2015 8:13:34 GMT -5

Things are moving slow at the moment. The Novak transfer case adapter is on the way, as is idler pullies, tensioner, accessory hardware, etc. I did get the truck crankshaft pulley mounted on the LSA crankshaft. It will have to be pinned, since I had to cut the LSA key off. I need to grab the crank-pinning tool from a buddy. Also, the ZL1 cover arrived, and fit under the cowl with about 1/2 inch clearance. I will have to cut a small access hole in the cowl to reach the rear cover bolts. No big deal. Also have to find somewhere to route the heater hoses. LSA crankshaft comparison to LS3. It has a key which had to be cut off to allow the truck pulley to be pressed on. Yes, that is an exhaust tubing adapter from Autozone. They work great on the press, come in a huge assortment of sizes, and are deep.     And the stock crossmember. It was too far forward, so I flipped it over. It's like Dodge said "Someday, people are going to want to put LS engines in these, so let's make it easy."  And the ZL1 cover in place   |

|

|

|

Post by casias on Dec 27, 2015 14:47:14 GMT -5

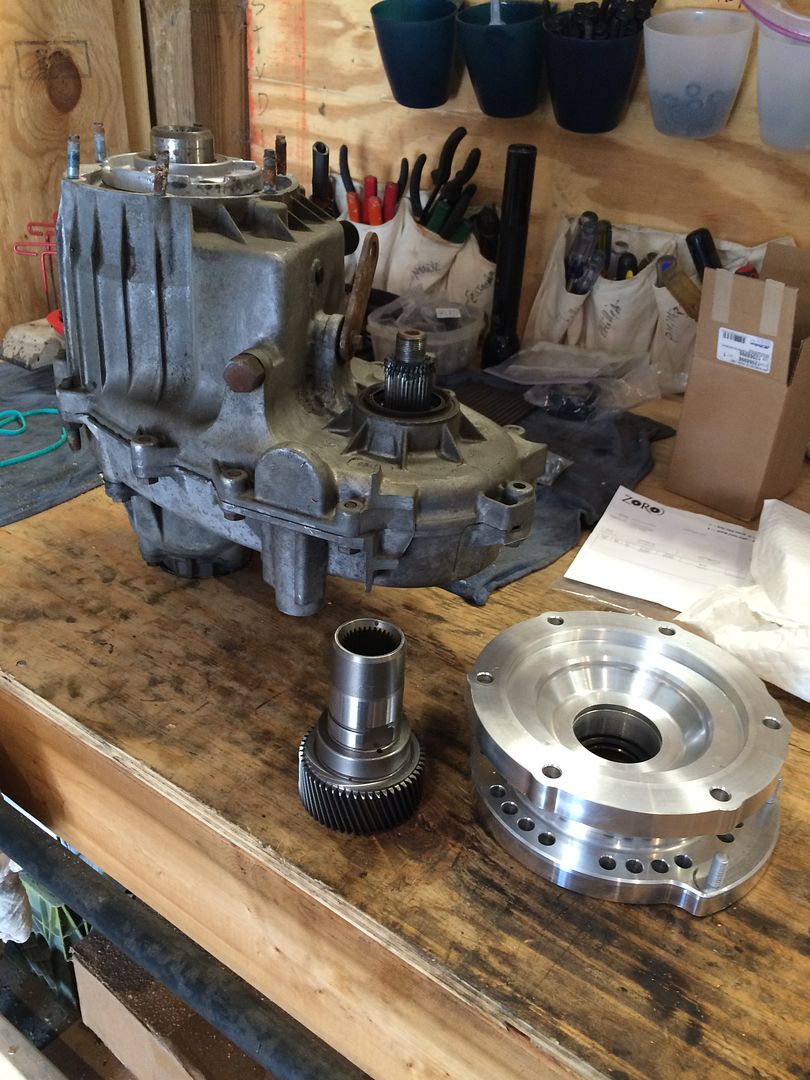

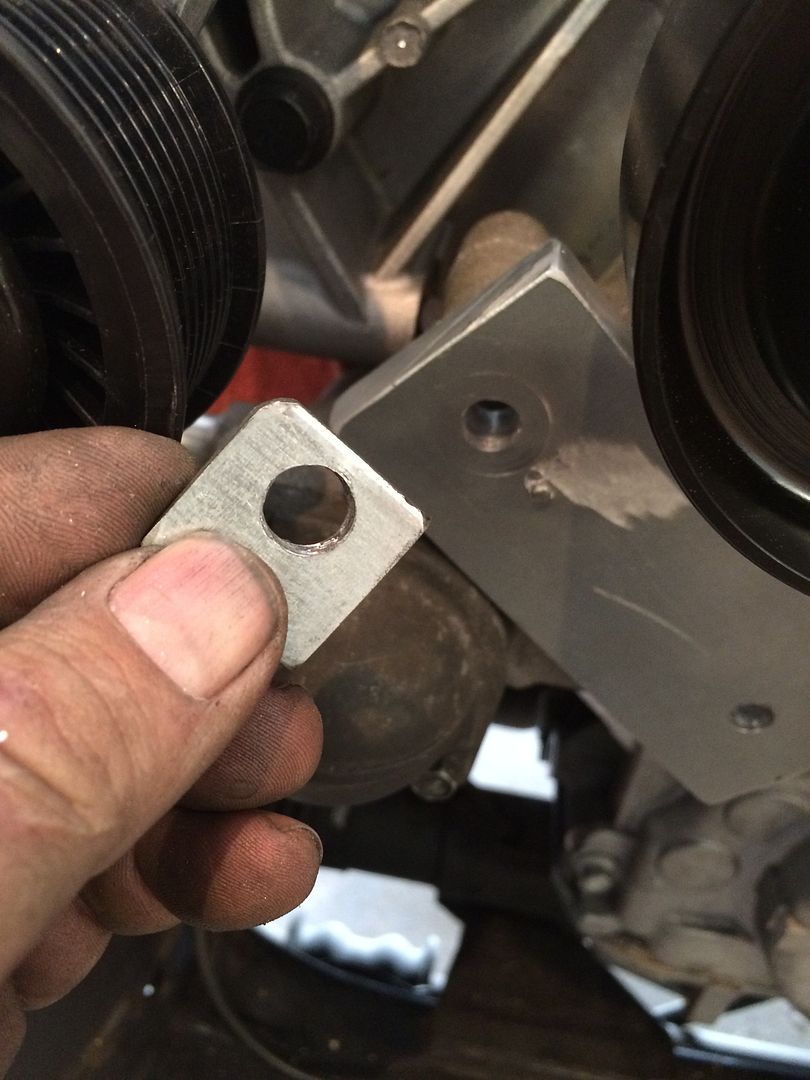

Ok, time for some updates from the holiday weekend. The Novak adapter arrived, so I swapped out the input shaft from 27 spline (?) to 32 spline to match with the 6l80 transmission. The adapter is billet aluminum, and really high quality. Kind of expensive, but...... I didn't want to wrestle the NP 242 around the table, and it should be flat when it is opened so the pieces don't spill out. So I cut a hole in the worktable and stood it on its tailshaft, using the front yoke as a spacer.    Opening up the case and pulling out the shift fork. There is a right way, and a pry-bar way.  Planetary and input shaft.  And time for another stupid pet trick. LS engines mostly use 10M X 1.5 metric bolts, but come in sizes from 23 mm to 135 mm. Dealers charge $ 2-3 for each bolt. Ouch. Also, if they don't have it in stock, you wait. If no one can figure out which one it is, you guess. And in my case, I drive 45 minutes round-trip for that experience. I went on ebay, and bought full-thread M10 X 1.5 bolts 135 mm long. I measure the bolt I need, thread a M10 die on the bolt, and cut it to length. Custom. Takes 2 minutes. Cost...a about .35 cents each. I think I bought 100 for around $35 shipped. Zoro.com or find them on ebay. Check it out. Pile of bolts.  Thead the appropriate die on. The handle helps hold the bolt while you cut it, and the die corrects the threads when you take it off.  I use a 4 1/2 inch angle grinder with a flap wheel to bevel the nose, and thread a nut on and off to check it before I use it. Quality assurance.  And, I made this Idler pulley bracket from 2 X 5 inch 1/2 inch thick 6061 aluminum stock. I put a small locator pin in, and put a small hole in the water pump mounting boss to keep the bracket from rotating. It doesn't take much.   And I had to add a shim to make the idler pulley true.  Tapped for the lower pulley. They upper pulley went into the other water pump boss  As shown here. Pretend the drill is the crankshaft.   |

|

|

|

Post by casias on Jan 10, 2016 9:27:00 GMT -5

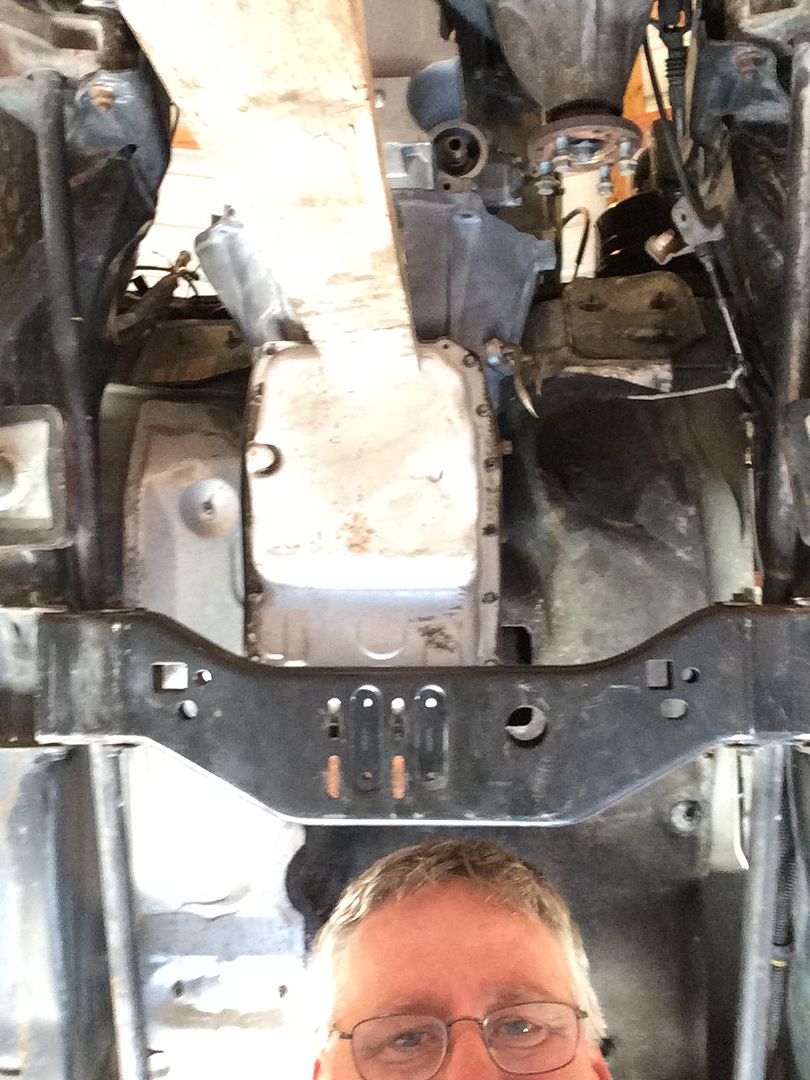

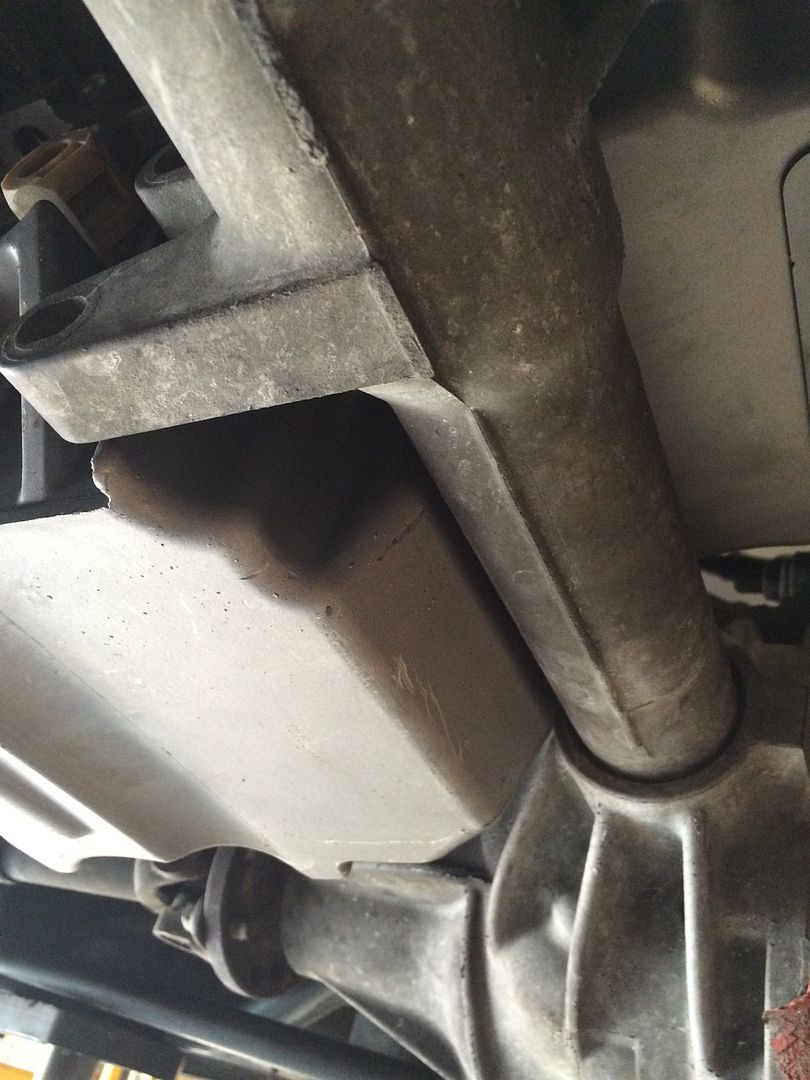

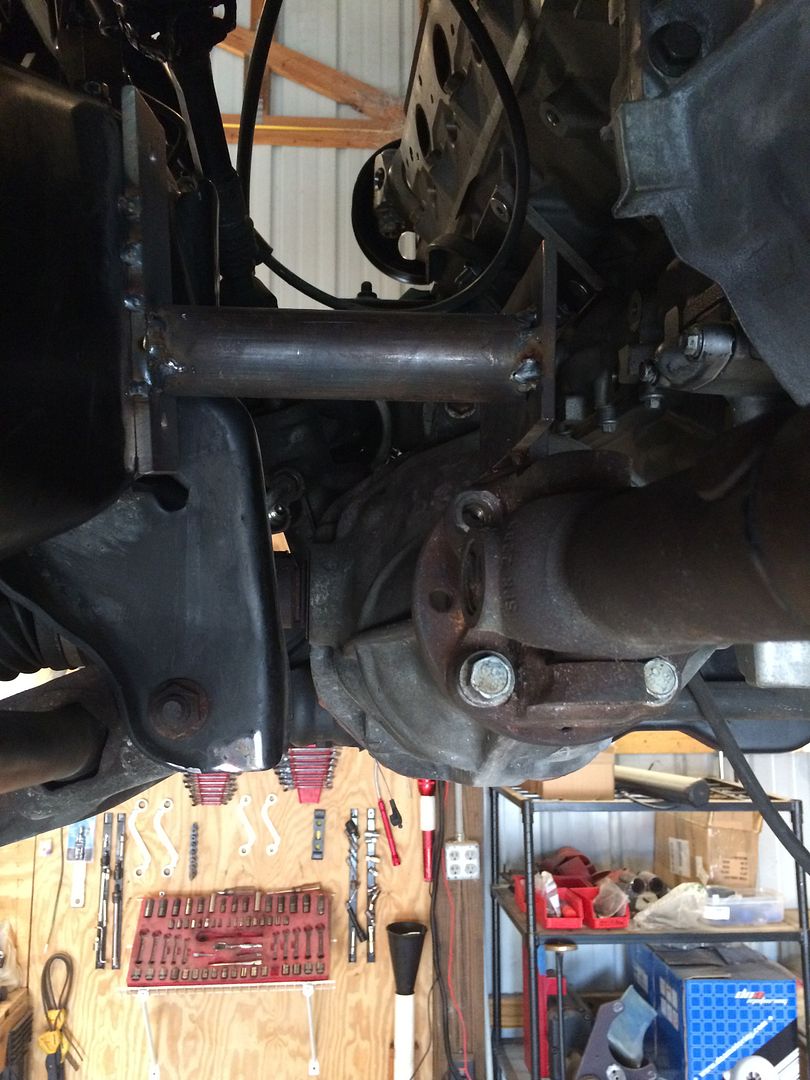

Time for a few updates. With the holiday, busy work schedule and extra call, I haven't been able to post stuff. But I have been moving forward. This week, it is all about driveline angles. After setting the motor where it would fit with the stock truck oil pan, I liked the clearances all the way around. If I wanted to spend $400 on a Holley oil pan, I could move the motor forward about an inch, and use the front and rear driveshafts again without modifying them. Crazy, huh? But, these driveshafts have 180k miles on them, so I figure having them rebuilt, modified and balanced is worth the $400 or so to have the work done. So, here are the pictures. After getting the NP242 installed using the Novak adapter, I made a transmission mount which is a combination of the GM mount (Flippded over, studs cut off) with the Novak-supplied adapter welded on. I welded a clean piece of 1/4 inch steel to the top of the transmission cross member (also flipped over), to give me a stable base. I drilled two 11/32 holes, and tapped for M10 bolts. The assembly is connected to the adapter with the supplied studs and nuts.    Here is the oil pan clearance to front axle.  Front axle about an inch short  Rear driveshaft installed  Needs to be a little shorter. The rubber seal is completely compressed, with the suspension at full extension.  Front axle support welded in. The original Durango drivetrain had a cast connector that secured the front axle to the transmission bell housing. This prevents the front axle from wrapping. I don't have that option this time, so I chose to attach it to the frame. This is temporary. Once the engine is out, I will make a more permanent brace using smaller tubing and webbing.  Front axle angle. With a double cardan on the transfer case side, this angle has to be 0-degree. Unfortunately, the picture doesn't show that this is actually 0-degree. It was hard to hold it exact and take a picture.  Now it's time to take it all out, build the motor, clean and paint, and put it all back in. Then wiring. More on that next week. has to be 0-degree. |

|

|

|

Post by casias on Jan 10, 2016 11:38:51 GMT -5

And, after some coffee, everything is back out. Transmission with Novak adapter  Pile of accessories  Transfer case  Bare engine ready to come out. I have to borrow the engine hoist later today for that.  |

|